Tribology – The Study of Lubrication, Friction, and Wear

How Do Metal-on-Metal Bearings Work?

Jin Dowson and Fisher50 showed that in both metal on metal bearings and ceramic on ceramic bearings, thick film lubrication can occur. This is recent information. Had this information been available at the time of Charnley's hip replacement development it would surely have influenced his choice of bearing materials. Thick film lubrication means that the articulating surfaces are not in sliding contact, instead they are separated by a synovial fluid film and this has profound implications for wear and friction of the bearing. Thick film lubrication is never possible in a metal on polyethylene or ceramic on polyethylene bearing because of the high surface roughness of polyethylene.

Boundary lubrication in Metal on Metal bearing. Synovial fluid does not separate articulating surfaces and wear will occur.

Thick film lubrication in Metal on Metal bearing. Synovial fluid completely separates articulating surfaces resulting in low friction and low wear.

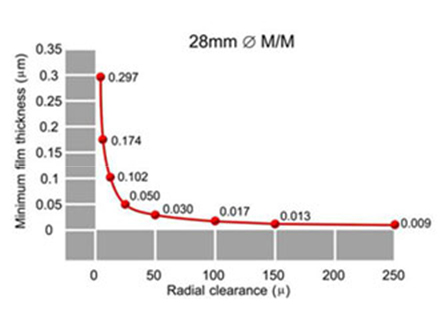

thickness versus clearance between the head and cup, then it can be seen that as the clearance decreases the fluid film thickness increases. At the commonly manufactured clearance, however, of 100 microns, the fluid film thickness that is generated is not enough to separate the articulating surfaces and asperity contact occurs and wear will result. In this 28mm metal on metal articulation, if the clearance is brought down to 25 microns then the fluid film generated is thick enough to completely separate the two articulating surfaces, however, achieving reproducibly at 25 micron clearance is a very difficult manufacturing task. (Data from Dr. Z. M. Jin, PhD)

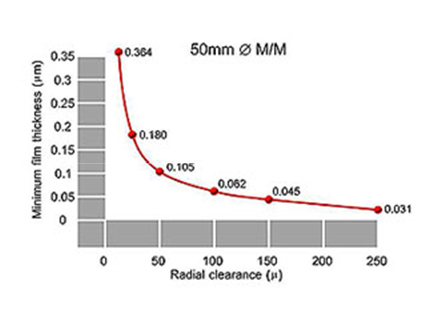

If we consider a 50mm metal on metal articulation (50mm is the most common head size used in resurfacing), then the plot of fluid film thickness against clearance looks much better and it can be seen that at the commonly manufactured clearance of 100 microns the fluid film thickness is increased four times compared to that generated with the same clearance in a 28mm metal on metal articulation. This fluid film thickness in the 50mm bearing is enough to completely separate the two articulating surfaces. This gives the exciting possibility that even with extreme usage wear of these bearings will not occur. (Data from Dr. Z. M. Jin, PhD)

Wear Retrieval Analysis of Birmingham Hip Resurfacing

-

Autopsy retrieved BHR Cup -

BHR Femoral Component

retrieved at revision for infection -

Mitutoyo Round test RA-300

It has been possible to examine very carefully three pairs of Birmingham Hip Resurfacing bearings retrieved from patients 6-18 months after implantation. One patient died of unrelated causes and bequeathed his hip for research. One bearing was retrieved at revision surgery for avascular necrosis of the femoral head and one bearing was retrieved at revision surgery for infection.

These bearings were all measured using a round test instrument with a resolution of 0.01 microns (Mitutoyo Round test RA-300). Multiple tracings were taken across the wear scar. All these patients were known to be active for at least the first six months after implantation. The published wear of 28mm diameter metal metal bearings indicate high initial wear.51 However, in these three pairs of retrieved resurfacing bearings no measurable wear was detected as compared to their individual manufactured form.

Frictional Torque

Thanks to the generosity of Professor Mike Wroblewski, we have been able to examine closely the Charnley pendulum comparator and the detail of the McKee metal on metal bearing used in that pendulum test.

This bearing was not manufactured to today's standards. It was an annular bearing rather than a polar bearing. This has marked implications for the lubrication of this bearing, and in addition the loading on the pendulum comparator was extremely low at 36kg. It is now well appreciated that peak load in the hip in an active person reaches six to nine times body weight, which means that a sportsman engaged in high level sport will generate a load across the hip joint in the region of 560kg.

We have built a pendulum apparatus to test the bearing of hip replacements under 560 kg of load. When testing a bearing using this apparatus, the pendulum is started at a fixed point and the number of swings, until standstill, is counted. A number of runs are then performed on each bearing.

Results obtained using 560kg Pendulum

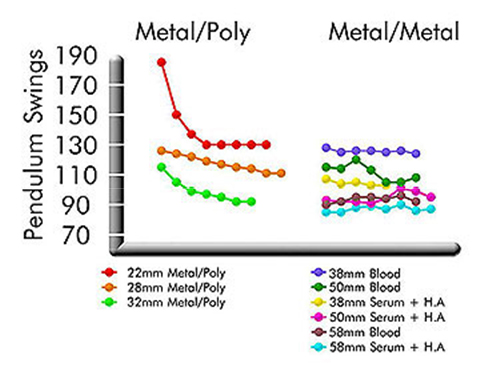

When the metal on polyethylene bearings are considered it can be seen that the 22, 28 and 32mm bearings decrease the number of swings per run and then come to a plateau. The different sized metal on metal bearings have been tested in serum and hyaluronic acid (substitute for synovial fluid) and blood. Of course these metal on metal bearings in patients are initially bathed in blood and later bathed in synovial fluid.

Unlike the results from Sir John Charnley's pendulum comparator, it can clearly be seen that the frictional torque of these different head sized Birmingham Hip Resurfacing bearings are not very different to a range of metal on polyethylene bearings in common clinical use.

It can be concluded, therefore, that frictional torque with these metal on metal bearings is not the issue that Sir John Charnley thought it would be. This low frictional torque from the metal on metal bearings is entirely consistent with the clinical experience of historic metal on metal joints having lasted 30 years or more.

© 2007 Smith & Nephew